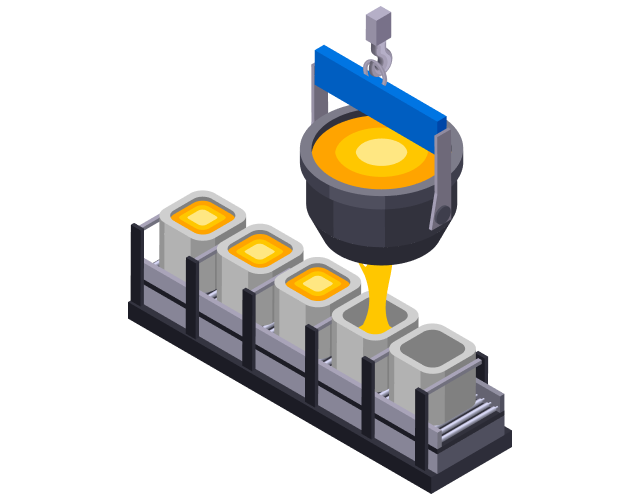

Aluminum Foundry: Boosting Fuel Economy in Vessels

Wiki Article

The Benefits of Dealing With a Full-Service Light Weight Aluminum Factory Partner

Collaborating with a full-service aluminum foundry partner presents distinctive benefits for services seeking effectiveness and high quality. These collaborations enhance style adaptability and streamline production processes. Furthermore, they use access to advanced modern technologies and competent expertise. This harmony not only enhances quality assurance but likewise promotes versatility in a busy market. Recognizing the full range of these advantages can considerably impact a firm's success in today's competitive landscape. What exists past these first advantages?Boosted Layout and Prototyping Capabilities

While many suppliers encounter limitations in design versatility, partnering with a full-service aluminum factory greatly boosts the style and prototyping process. Such partnerships assist in accessibility to advanced modern technologies and know-how, allowing for more innovative styles that may or else be unattainable. The shop's capacities commonly include computer-aided design (CAD) and fast prototyping, which enable producers to imagine and refine their ideas before last production.Furthermore, these foundries can provide useful responses during the style stage, assisting to recognize possible issues beforehand and suggesting adjustments that enhance manufacturability. This cooperation decreases the threat of pricey mistakes and lowers time-to-market for brand-new items. A full-service factory can fit a large variety of light weight aluminum alloys, making it possible for designers to select products that best fit their particular efficiency needs. In general, this partnership fosters an extra active and responsive layout process, inevitably benefiting completion item.

Structured Manufacturing Processes

Collective design initiatives with a full-service aluminum foundry not only enhance prototyping yet also result in streamlined production processes. By incorporating style and production from the beginning, these partnerships permit the identification and elimination of possible traffic jams early in the process. With access to seasoned employees and innovative technologies, foundries can maximize casting methods and fine-tune production methods, resulting in much shorter preparation and enhanced efficiency.A full-service shop uses substantial solutions, including tooling, ending up, and top quality assurance, all under one roof. This debt consolidation reduces the need for several vendors, decreasing interaction delays and imbalances. Aluminum Foundry. Additionally, the continual comments loop established in between design and production groups ensures that any issues are without delay attended to, maintaining a smooth functional flow. Inevitably, the synergy created with these collective efforts not only improves item quality yet also speeds up time-to-market, providing substantial advantages in today's affordable landscape

Cost-Effectiveness and Resource Optimization

When partnering with a full-service light weight aluminum cost-effectiveness, foundry and resource optimization are crucial factors. By lowering production costs and making sure efficient resource allocation, business can accomplish considerable savings while maintaining high quality. Structured manufacturing processes additionally boost these advantages, making collaboration with a skilled factory companion a calculated choice.Minimized Manufacturing Expenses

A partnership with a full-service aluminum foundry can greatly reduce production costs, making it an attractive choice for manufacturers. Aluminum Casting. By leveraging specific equipment and competence, these shops improve production procedures, minimizing waste and inefficiencies. This brings about decrease functional prices and makes it possible for producers to provide competitive rates in the market. Furthermore, full-service foundries often give bulk getting choices for raw products, which can significantly reduce product prices. Their ability to handle different solutions internal, such as casting, machining, and finishing, eliminates the need for numerous vendors, decreasing overhead expenses. Inevitably, the assimilation of solutions and maximized production methods contribute to an extra economical manufacturing procedure, allowing business to focus on growth and technology while preserving earningsEffective Source Allocation

Optimizing resource allotment is key to boosting general production effectiveness. A full-service light weight aluminum factory companion supplies valuable proficiency in optimizing making use of materials, labor, and machinery, making certain that sources are utilized successfully. By leveraging knowledgeable workers and innovative technologies, these factories decrease waste and decrease excess stock, causing substantial expense savings. Additionally, their capability to adjust to transforming task needs permits far better responsiveness and source administration. This tactical allocation not just improves manufacturing timelines but additionally enhances item high quality by ensuring that the right resources are employed at the ideal phases of production. As a result, firms can attain a more sustainable operation while keeping competitive pricing and meeting consumer demands effectively.Structured Manufacturing Processes

Streamlined production processes play an important role in boosting both cost-effectiveness and resource optimization within light weight aluminum shops. By incorporating lean techniques and innovative technologies, full-service factories lessen waste and improve production performance. This strategy enables faster turnaround times, which lowers labor expenses and raises output. Additionally, a well-organized process guarantees that materials are made use of sensibly, consequently lowering total production expenses.Furthermore, standardized treatments assist in much better quality control, reducing the possibility of issues and revamp. Because of this, clients take advantage of consistent product quality while preserving financial constraints. Inevitably, partnering with a full-service light weight aluminum factory that prioritizes structured manufacturing processes can meaningfully boost a company's operational performance and earnings in today's open market.

Accessibility to Advanced Technologies and Experience

Access to advanced modern technologies and competence is a significant advantage of partnering with a full-service light weight aluminum foundry. Using cutting-edge manufacturing processes improves manufacturing efficiency and product quality. Furthermore, a knowledgeable technical workforce assurances that tasks are implemented with precision and technology.Cutting-Edge Production Processes

A wide range of markets take advantage of the cutting-edge production procedures offered by a full-service light weight aluminum factory companion. These innovative methods boost production performance and accuracy, enabling the production of intricate light weight aluminum components customized to certain applications. Technologies such as additive production and accuracy casting allow factories to minimize waste and lessen preparations, ensuring a quicker turn-around for clients. Furthermore, the integration of automation and digital innovations simplifies procedures, boosting overall productivity. By utilizing modern tools and techniques, shops can continually supply high-grade items that meet rigorous industry standards. This commitment to embracing the most recent developments positions full-service light weight aluminum foundry partners as leaders on the market, supplying considerable benefits to their clients across different sectors.Experienced Technical Labor Force

While numerous markets encounter difficulties in locating skilled labor, full-service light weight aluminum factory companions stand out by utilizing a highly educated technical workforce that is efficient in innovative technologies and industry ideal methods. This workforce is skilled at using state-of-the-art tools and software program, making sure that manufacturing processes are reliable and exact. Their expertise enables for the smooth assimilation of cutting-edge techniques, leading to premium product top quality and reduced lead times. Furthermore, continual training and development programs are applied to look at this website keep the workforce upgraded on the newest improvements in light weight aluminum spreading and handling. By leveraging this proficient labor, foundries can react efficiently to intricate task needs, ultimately giving clients with dependable services customized to their details demands.

Boosted Quality Control and Guarantee

Quality assurance and guarantee stand as crucial aspects in the operations of a full-service Aluminum Casting light weight aluminum factory. These procedures guarantee that the products produced satisfy strict market requirements and client specs. A dedicated quality monitoring system, frequently integrated throughout the manufacturing phases, enables continuous monitoring and analysis of methods and materials.Full-service aluminum shops utilize innovative screening methods, including non-destructive testing and metallurgical evaluation, to recognize potential defects early in the manufacturing process. This positive strategy mitigates the threat of expensive rework and guarantees that finished products are long lasting and reliable. Additionally, a society of high quality within the labor force enhances accountability and promotes a commitment to excellence.

Flexibility and Versatility to Market Changes

Adjusting to market modifications is essential for full-service aluminum shops, allowing them to respond swiftly to evolving client demands and sector trends. An adaptable foundry can readjust production routines, modify styles, and carry out brand-new innovations quickly, ensuring that clients get prompt and appropriate options. This versatility not only enhances client fulfillment however additionally fosters long-term partnerships.Moreover, a full-service light weight aluminum factory's ability to pivot in action to market fluctuations enables organizations to utilize on emerging possibilities. By remaining in harmony with shifts sought after, such as a rise in sustainable items or innovations in light-weight products, these factories can introduce and improve their offerings accordingly. This responsiveness is an important asset in an affordable landscape, as it aids clients decrease lead times and manage costs properly. Ultimately, adaptability and versatility placement full-service aluminum factories as very useful companions in steering the complexities of the modern-day marketplace.

Regularly Asked Concerns

What Kinds Of Light Weight Aluminum Alloys Do Full-Service Factories Typically Use?

Full-service foundries typically make use of numerous light weight aluminum alloys, including 1xxx, 2xxx, 3xxx, 4xxx, 6xxx, 5xxx, and 7xxx collection. Each alloy offers particular applications, offering different homes like stamina, deterioration resistance, click here for info and weldability tailored to sector needs.How Can I Determine the very best Shop Partner for My Task?

To identify the very best factory partner, one must analyze their experience, abilities, quality assurance processes, consumer testimonials, and responsiveness. Contrasting quotes and seeing facilities can likewise supply insights right into their dependability and experience.

What Is the Lead Time for Custom-made Aluminum Castings?

Do Full-Service Foundries Deal Design Appointment Solutions?

Yes, full-service factories generally provide design consultation services. This assistance helps customers refine their ideas, making certain perfect performance and manufacturability, while additionally dealing with any technological obstacles that might occur throughout the aluminum casting process.What Industries Commonly Gain From Light Weight Aluminum Foundry Partnerships?

Industries such as vehicle, aerospace, building, and electronics commonly profit from light weight aluminum factory partnerships. These fields count on aluminum's lightweight and durable homes for producing parts, improving performance, and meeting rigid industry criteria efficiently.While numerous makers face restrictions in style versatility, partnering with a full-service light weight aluminum shop substantially improves the layout and prototyping procedure. Collective style initiatives with a full-service aluminum factory not only improve prototyping yet also lead to streamlined production procedures. A partnership with a full-service aluminum shop can greatly lower production expenses, making it an appealing choice for manufacturers. A wide variety of sectors benefit from the advanced manufacturing procedures offered by a full-service light weight aluminum factory companion. Full-service light weight aluminum shops employ advanced screening techniques, including non-destructive testing and metallurgical analysis, to recognize prospective issues early in the manufacturing process.

Report this wiki page